Is hard-anodized aluminum better than aluminum, ceramic or 3-ply stainless-steel?

By Editor Team | September 30, 2022

When you’re about to step into the nonstick garden—unless you’re a cooking pro—you’ll be stumped with dozens of this and that questions like: should I buy a nonstick or hard-anodized pan? Ceramic is the best nonstick, right? Does hard-anodized cookware cook better than 3-ply nonstick? or Which nonstick pots and pans work with my induction stove?

To clear all these issues, we break down the complicated matters and try to explain things on a practical level, step by step.

Hard anodized—or hard anodized aluminum—is hardening a soft aluminum surface electrochemically to create a thick layer of aluminum oxide on the surfaces, which makes it much stronger than plain aluminum so that it can resist dents and corrosions.

Back to the 1960s, while Mr. Ulam of All-Clad was busy strengthening aluminum with the new ‘clad technique’, Mr. Kasperzak, the founder of Commercial Aluminum Cookware—a.k.a Calphalon— , invented hard-anodized aluminum by using a process adopted from the aerospace industry.

At that time, this innovation was warmly embraced by the professional culinary community as acquiring the same heat transmission ability as regular aluminum but had a stronger build and didn’t leach aluminum into food.

Back then, hard-anodized cookware came in a bare surface—no nonstick coating. So, even though it has a more slippery surface, food still sticks and easily gets blackens that made hard to cook and cleanup.

Heck, while the anodized process successes to strengthen aluminum, it can’t improve the nonstick power to the pots and pans. As a result, by the mid-1990s, most companies—even Calphalon—apply nonstick coatings on their cookware surfaces to employ the stick-less property.

That’s a reason why you’ll find that most hard-anodized cookware in the market now comes with nonstick coatings, either Teflon or not.

It can be said: hard anodized aluminum these days is actually nonstick cookware.

Perhaps, Calphalon Commercial DS9D is an only bare anodized aluminum existed now. It seems to be discontinued, but you can find some pieces on eBay, Amazon or some retails left.

Calphalon Commercial DS9D is a barely found hard-anodized cookware that has no nonstick coating.

So, it can be said: hard anodized cookware these days is actually a type of nonstick cookware since using a nonstick coating. That’s why the manufacturers label “hard-anodized aluminum nonstick” on their products.

To delve into further questions without confusion, you should figure out the construction of nonstick cookware you have and learns some definitions of nonstick things.

For any coated cookware, these are major types of nonstick cookware structure you’ll find. Each has its strengths and weaknesses.

Left to Right: Misen fry pan, Jean-Patrique the whatever pan, Ninja Foodi NeverStick

Aluminum is cheap and feather-y lightweight. As a great heat conductor, it’s flash-fast to heat up and cool down but retains heat poorly. It’s regularly used in a restaurant setting as an economical tool that requires minimal upkeep. In a downside, it’s fragile—easy to warp, dent or damage, and it has a short lifespan—and gives the best outcomes only on gas and hot coil stoves.

Cast aluminum often has a thicker aluminum body than regular aluminum or some hard-anodized, which makes it conduct and retain heat better. It’s sturdier than regular aluminum but not as hard as hard-anodized.

Hard-anodized aluminum possesses the good properties of aluminum—lightweight and excellent heat conduction—while offers much tougher than regular aluminum from the electro-chemical method on its exterior. Learn more about the characteristic of this material here.

Left to Right: Le Creuset toughened nonstick pro, GreenPan Treviso, Made In nonstick

Forged anodized aluminum applies two approaches together—forging (a process that alters the crystalline structure of the material) and anodizing—to make cookware becomes tougher in the whole build and at the surface.

Stainless-Steel with a disk base is a coated stainless-steel that has an aluminum disk inside the bottom of the pan, which mostly makes it work for induction cooking. Among the contenders, it ranks the worst in heat responsiveness and evenness, but it’s visibly more robust than those all-aluminum players.

Stainless-Steel Clad is a multi-ply stainless-steel cookware that has a nonstick coating—known as 3-ply or 5-ply with nonstick. It’s substantially tougher and weightier than aluminum and hard-anodized. The cooking efficiency depends on the thickness of an aluminum layer(s). It’s mostly found induction-compatible.

Some manufacturers claims that their hard-anodized aluminum products are better and almost twice as hard as stainless-steel—is it true? Here’re some facts about hard-anodized cookware, on a paring to coated stainless-steel:

When talking about nonstick, a most common confusion is people usually mixing the structure with the coating. To clear the myth, you’ll need to know the difference between the two:

Structure—as mentioned above—is the material and method to make cookware that will determine its heat character, durability or longevity.

Nonstick coating (cooking surface) is a surface engineered to prevent food from sticking to it. There’re several nonstick coatings used in cookware products, but the common staples are:

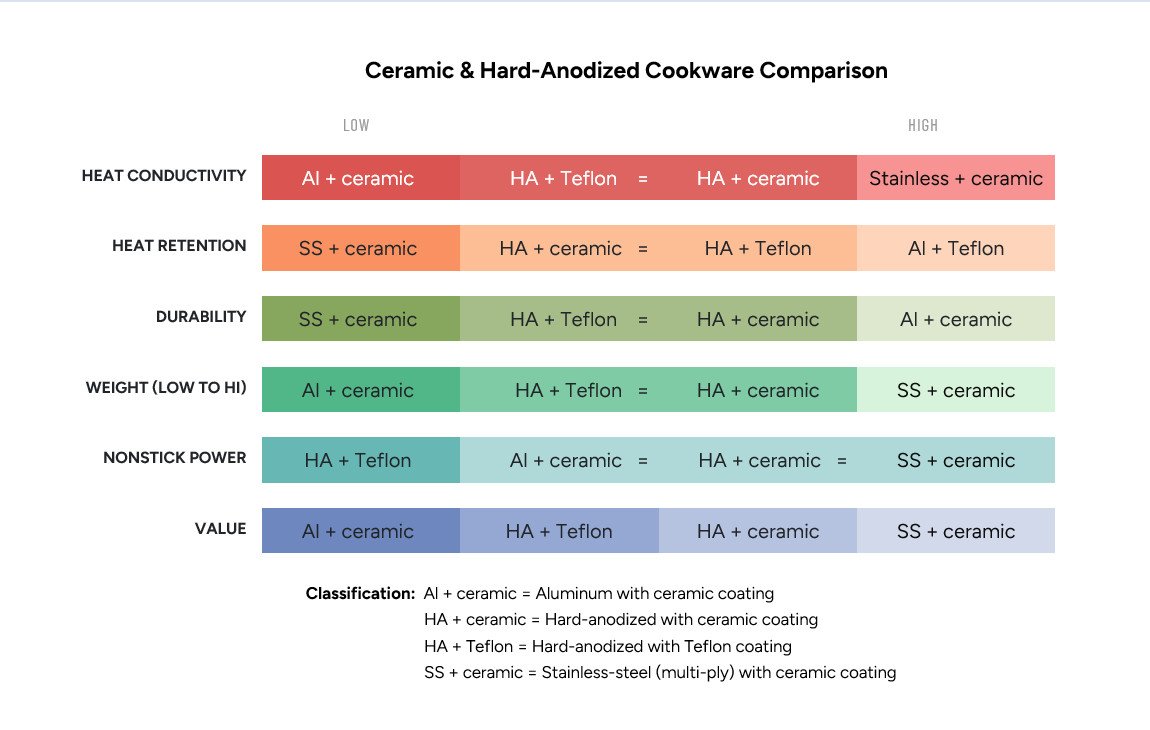

For a clearer view, we did a comparison chart of performance, durability, weight and value of each material on both coatings below. You’ll see that the heat characteristic of cookware rests on its material structure, whereas the nonstick power is up to the coating it uses. In common, Teflon is more effective than ceramic.

So, if you ask which one is better: hard-anodized or ceramic, the answer is you can’t compare the structure of the cookware (hard-anodized) with the coating (ceramic) since they’re not the same thing at the first place.

But if you compare between hard-anodized with ceramic and hard-anodized with Teflon, we got the answer: they’re equivalent in thermal ability, but Teflon is a better performer for nonstick power and durability.

In reality, you don't need to choose one because you can have both since there’re many hard-anodized products that has a ceramic coating out there. Many GreenPan collections, like the Valencia Pro, the SearSmart or the Reserve, are the samples.

If you have no time to dig deep in this guide, these’re our short-cut conclusions to clear the doubts: